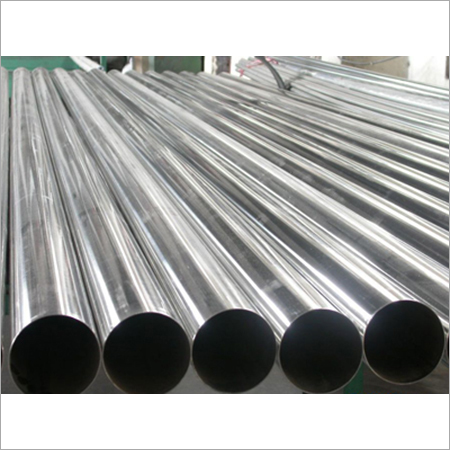

Nickel Tube

Nickel Tube Specification

- Product Type

- Nickel Tube

- Shape

- Round

- Elongation

- 40%-50%

- Strength

- Tensile Strength: 380-620 MPa

- Hardness

- Rockwell B75

- Resistance

- High corrosion and oxidation resistance

- Grade

- Nickel 200 / 201

- Melting Range

- 1435C - 1455C

- Density

- 8.9 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Pure Nickel (Ni > 99%)

- Application

- Chemical Processing, Aerospace, Power Generation

- Color

- Silver

- Electrical Conductivity

- 14.3 MS/m

- Surface Finish

- Bright / Annealed

- Outer Diameter Range

- 6 mm - 150 mm

- Standards

- ASTM B161, ASTM B163

- Length

- Up to 6 meters or custom cut

- Thermal Conductivity

- 90.9 W/mK

- Weldability

- Good

- Magnetism

- Non-magnetic in annealed condition

- Wall Thickness

- 0.5 mm - 10 mm

Nickel Tube Trade Information

- Minimum Order Quantity

- 10 Tons

- Supply Ability

- 100 Tons Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Nickel Tube

Turn out to be a client centric organization among our clients we are regarded as an authentic manufacturer, wholesaler, distributor, supplier and exporter of a quality range of Nickel Tube. This excellent product range is used in sector like automotive, food processing, pharmaceutical, power generation, biotechnology, waste treatment, coal and gas processing. This tube is installed in various industrial applications at the place where high stress is requisite with surface stability. To dispatch best quality products, this Nickel Tube goes through various testing procedures by our quality controllers to make certain the quality of the products.

Features:

- Light weight structure

- Heat resistant

- Excellent finish

Sturdy construction, best performance and longer service life are best features of our tubes. Also, these have very good non-restrictive and electrical properties.

Applications :

- Aviation

- Electronic

- Engineering

- Medical

- Metallurgy

- Military

- Petrochemical

- Salt-Making

- Sports

- Textile

- Our company is verified by third-party inspectors

- Over 10 years of experience

- Assorted zirconium products are exported at rate exceeding 500 T yearly

- We have ISO:9000 certification

- Purchasing cost is less and we offer professional services

- 1st layer: Moisture-proof paper

- 2nd layer: Kraft paper

- 3rd layer: Foam plastics in every all side of plywood case

- Final layer: Plywood case

Transportation :

- Air transport is used for convey goods to Beijing or Shanghai airport

- Goods are shipped by TNT, DHL, Fedex, UPS, EMS and others

- Sea transport is done to Shanghai port and Tianjin port.

Technical Specification :

| Grade | Technology | Status | Size(ODWTL mm) | Specification |

| N4, N5, | Hot rolling | MY | 5-1101.0-102000-9000 | ASTM B161 GB/T2882 |

| Weld | MY | 89-10003.0-101000-9000 |

| Condition and Size | Tensile strength, min, psi(Mpa) | Yield Strength(0.2%offset) min psi (Mpa) | Elongation in 2 or 50 min(or 4D), min% |

| Nickel Low carbon nickel | Nickel Low carbon nickel | Nickel Low carbon nickel | |

| Annealed 5 in (127mm) and under OD | 55 000(380) | 15 000(105) | 35 35 |

| Over sin.(127mm) OD | 55 000(380) | 12 000(80) | 40 40 |

| Stress-relieved all sizes | 65 000(450) | 40 000(275) | 15 15 |

Exceptional Physical and Mechanical Properties

Nickel Tubes boast remarkable tensile strength between 380 and 620 MPa and an elongation of 40%-50%, ensuring durability in severe environments. With a high melting range of 1435C to 1455C and superior resistance to corrosion and oxidation, these tubes are built to withstand challenging industrial applications.

Precision Manufacturing & Compliance

Produced under stringent quality control, our Nickel Tubes comply with ASTM B161 and ASTM B163 standards. Available in bright or annealed finishes, they are supplied as round, silver-color tubes and can be custom cut to required lengths, ensuring precise fit and easy integration into your project.

Versatile Industrial Applications

Thanks to their high purity, excellent conductivity, and non-magnetic characteristics in the annealed state, these Nickel Tubes are widely used in the chemical, aerospace, and power generation sectors. Their high resistance to aggressive environments makes them a reliable choice for critical operations.

FAQs of Nickel Tube:

Q: How are your Nickel Tubes typically used in industrial applications?

A: Nickel Tubes are esteemed for their superior resistance to corrosion and oxidation, making them suitable for chemical processing, aerospace components, and power generation systems. Their high purity and mechanical stability ensure reliable performance in aggressive or high-temperature environments.Q: What is the process for ordering custom-cut Nickel Tubes?

A: Simply provide the desired outer diameter, wall thickness, and length when placing your order. We accommodate custom requirements up to 6 meters, allowing you to receive tubes precisely tailored for your application.Q: When should I choose Nickel 200 or 201 grade tubes for my project?

A: Nickel 200 is ideal for applications requiring excellent mechanical properties and electrical conductivity, while Nickel 201 is preferred in environments where low carbon content is critical to preventing embrittlement at high temperatures.Q: Where are your Nickel Tubes manufactured and supplied from?

A: Our Nickel Tubes are manufactured and supplied from China, where we operate as a distributor, exporter, manufacturer, supplier, and trader to serve both domestic and international markets.Q: What benefits do the annealed and bright finishes offer for Nickel Tubes?

A: Annealed tubes provide enhanced ductility and non-magnetic properties, supporting intricate forming and welding processes. Bright finishes ensure a clean, visually appealing surface and aid in corrosion resistance, making them ideal for demanding industrial uses.Q: How does the high conductivity of your Nickel Tubes impact their usage?

A: With thermal conductivity of 90.9 W/mK and electrical conductivity of 14.3 MS/m, these tubes are excellent for applications that require efficient heat transfer or electrical conduction, such as in heat exchangers and electronic components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nickel Products Category

Nickel Wire

Minimum Order Quantity : 10 Tons

Product Type : Nickel

Strength : High

Color : Silver

Grade : Pure Nickel

Hardness : Hard

Nickel Foil

Minimum Order Quantity : 10 Tons

Product Type : Nickel

Strength : High

Color : Silver

Grade : Pure Nickel

Hardness : Hard

Nickel Sheet

Minimum Order Quantity : 10 Tons

Product Type : Nickel

Strength : High

Color : Silver

Grade : Pure Nickel

Hardness : Hard

Nickel Plate

Minimum Order Quantity : 10 Tons

Product Type : Nickel

Strength : High

Color : Silver

Grade : Pure Nickel

Hardness : Hard

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry